Tread

Casting Tread

Casting

By

Dewey H.

The

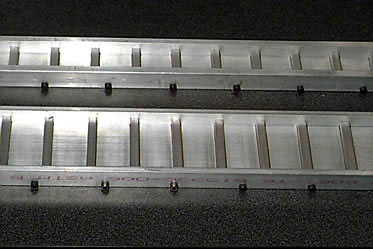

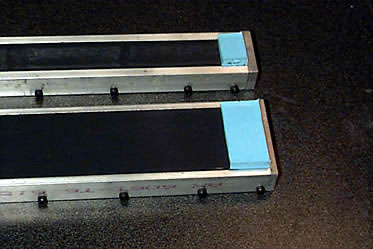

molds are 4 feet long and made from aluminum. They must be sprayed

with a mold release before casting.

The chemicals to make the rubber must be measured precisely with

a digital scale. There is only a 2% error rate allowed before the

rubber won't galvanize. The black pigment is added after the chemicals

are mixed.

The

rubber is poured just enough to cover the ribs of the mold. The

molds must then be bounced several times to remove any air bubbles.

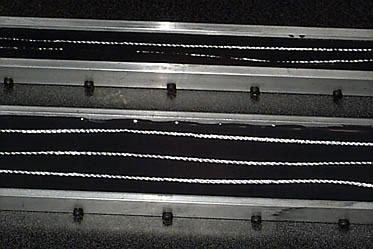

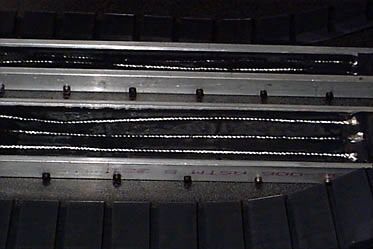

After the rubber reaches it's gel time (the point where it is no

longer a liquid) nylon cording is placed along the length of the

molds.

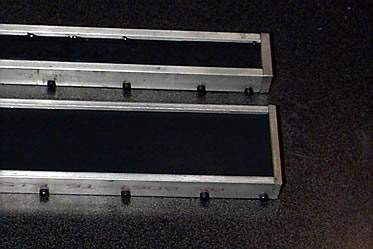

Silicone pads are then placed on all ends of the molds. These will

allow the next attached casting's nylon cording an overlap area.

Rubber is then poured to the level mark once the silicone plugs

are in place.

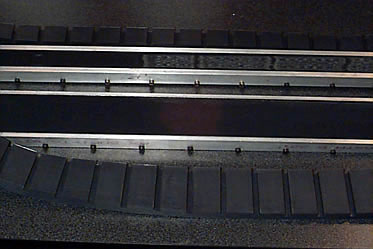

Once the rubber is set (12 to 24 hours) the treads are removed and

reset into the mold. This is where the sizing can be varied.

The same procedure is followed as in the first two steps with the

nylon cording run also into the areas that the silicone plugs were

in. This gives strength to the "butt splice" where the

ends meet.

The treads are now complete. They are treated with a rubber preservative

before installing. New rubber has a tendancy to be slightly sticky

until treated. Full curing takes several days.

|