Sensor

Holders Sensor

Holders

By

Craig Reinbrecht

The first pair of sensors/holders I made, I presented to Bob May

for his fan-built robot at Fright Vision 2000.

A year later I finally made a second pair for my robot! I made this

set to fit onto my tiny MicroMo motors and this is how they were

made.

Materials Needed: Clean (unused) one quart paint can, epoxy,

epoxy putty, 1/4" brass rod, and two 4-40 round head slotted

screws (3/16" long)

To make The Sensors:

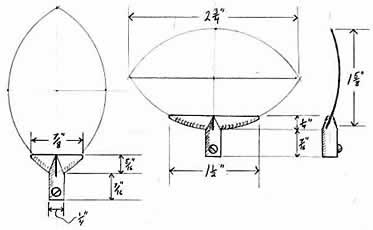

To make my sensors I used a one quart paint can that I purchased

new at a paint store for about $1.50. I studied pictures of the

originals to verify that the 2" radius of the paint can looks

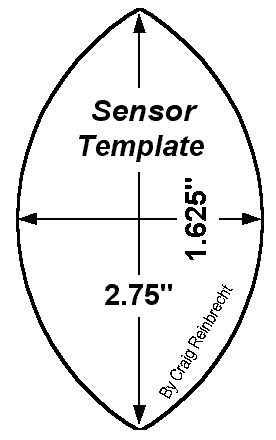

just right when the sensor is finished. Print (at 150dpi) and cut

out the sensor template which is 2.75" by 1.625" and trace

it onto the can with a Sharpie marker.

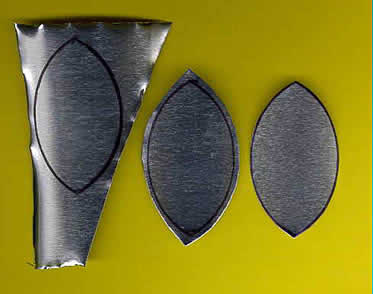

I found the sheet metal in the cans was so thin it could be cut

with scissors, so rough cut the sensors first leaving an extra 1/8"

all the way around, then cut them close to the final size. That

little trick keeps the thin metal from creasing while you cut it.

(TIP: Don't use your wife's good sewing shears!)

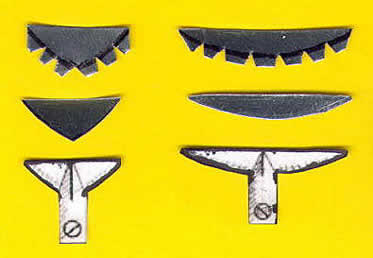

Because the metal is so thin and flimsy, I used epoxy to glue two

pieces together. The resulting epoxy sandwich came out very ridged

and strong, yet still fairly thin.

I carefully cleaned up the edges on my sanding disk to get the shape

perfect. Next, sand the shiny surfaces and the edges by hand with

some 220 grit sandpaper to prepare them for primer. You might want

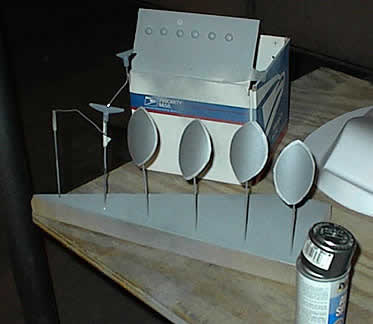

to make a simple painting stand with some coat-hanger wire and a

little bit of masking tape to make the painting process easier.

I sanded and primed the sensors a couple times to get a good base

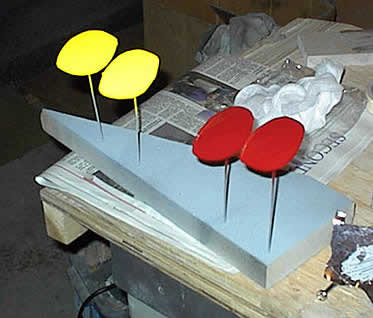

ready for the paint. Make sure there is no metal exposed. To paint

the sensors to the second/third season paint scheme of red and yellow

with silver on back, it is a good idea to get some "safe-release"

masking tape (available in the paint section of any home store).

This doesn't stick as ferociously as standard masking tape, so it

won't peel up your carefully painted surfaces. While painting the

backs silver, cover the fronts with the safe-release masking tape

and visa versa. The red, yellow, and silver paints will over spray

onto the opposite surface without it.

Done with the sensors!

To make the Holders:

The holders are made from plumbers epoxy and some 1/4" round

brass rod. Plumbers Epoxy is a great substance that I used in many

parts of my robot and is great for attaching screws to the inside

of the torso. It can be found in the plumbing section of Home Depot

right by the solder.

To make the holders, I first took scrap sensors (cut out of the

one quartpaint can) and stacked 3 together so the stack was a little

thicker than a finished sensor. Then I cut very small pieces of

the leftover thin sheet metal from the can to wrap around the tip

of the sensor emulating the holder and about that size.

This is an important step, and it pays to do this part carefully.

I actually made a back piece with tabs, that raps around over the

front piece, and made this form very tight to the scrap sensors.

Small side cutting wire cutters (snips) work good to cut the little

pieces.

Next, carefully scuff up the shinny metal with some sand paper,

so theepoxy putty has something to bite into. Cover the small sheet

metal"holder" with epoxy putty so there is a nice thick

layer of putty, but becareful to keep it off the scrap sensors!

After about twelve hours theplumbers epoxy is thoroughly dry and

hard as a rock. This stuff is very strong and bonds well.

I carefully pull out the scrap sensors so a very nice form fitting

slit is left in the top of the holder. Now you have to file or sand

the holder very carefully to the correct shape using the best photo's

as a guide.

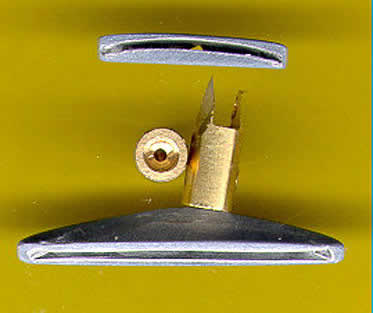

To make the round shaft I used 1/4" solid brass rod that you

can get at a home store or hobby store. Cut it close to length,

about 11/16". To make the sensors to fit onto the MicroMo motor

shaft, or any other motor shaft, you will need to drill a hole in

the bottom of the rod to match the size of the motor shaft. First,

make a simple jig to hold the rod so it can be held securely so

perfectly straight holes can be easily drilled using a drill press

(If you don't have a drill press, you can use a thick walled 1/4"

aluminum tube instead of the solid brass rod). To make the holding

jig use a scrap piece of wood at least 3/4" thick and drill

two 1/4" holes about 1/2" deep. Put the two brass rod

pieces into the holes. Now you can safely and easily drill the holes

in the bottoms of the rod being careful to get the holes perfectly

centered. I believe a 1/16" hole (my smallest drill bit) was

perfect for the MicroMo motor shaft. After you drill the hole for

the motor shaft, you must drill the hole for the 4-40 round slot

head screw that will go in the side of the shaft. This will make

the holder look authentic, plus it can actually work to hold the

sensor onto the shaft. Drill the screw hole more than half way through,

but be careful not to drill all the way through! The hole for the

screw must be tapped and I had to buy three 4-40 taps to accomplish

it. The first tap was used to get the threads started, then break

a little off of the tip of the second to go a little deeper, then

a little more off the third to get the threads cut all the way into

the center of the rod. Make sure to use some oil or tapping fluid

to make this MUCH easier.

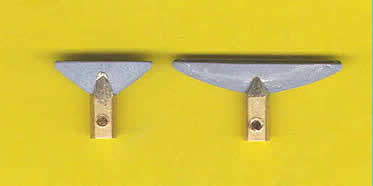

Next, securing the little brass rod piece in a vise (with wood to

protect the rod) cut a slit in the top of the rod that the holder

part can fit into. I used a hacksaw and a small file. Carefully

file the outside sides of the slit as you see in the pictures to

match the original look.Now it is time to attach the holder to the

rod using a very small amount of epoxy putty.

When that is thoroughly dry, do some final sanding to get a smooth

uni-body look, then prime and paint!

A very tiny dab of epoxy will hold the sensor in the holder, and

you are done!

|