Homemade

Torso #1 Homemade

Torso #1

By

Dave Painter

And

they said it couldn't be done...

Before

I begin, let me say that this was a lot of work. Let me also state

that that's exactly why I decided to do this project, It's big,

complicated, and possibly the most fun I've ever had building anything.

It is very important to have all of your measurements figured out

before you start. I spent a almost a year (on & off) working

on a set of drawings before I started .

Step

1

The torso consists of two rings and a center conical tube. I realize

that there is quite a lot more to it than that, but essentially

that's it.I began by choosing the materials. I chose to make the

rings from pine. Since I began I've discovered several high density

foams that are available from plastics stores which may have proved

easier, but heck, You can buy pine at Home Depot.

Step 2

I cut the pine into trapezoids that fit together to form a ring

of sufficient diameter and laminated them together using wood glue.

I made the stacks several thickness' high. This technique is the

same one you'd use if you were making a turned wooden bowl. Now,

since we are building this torso ourselves, and we are not forking

out the mega-bucks for a pre-fab, we are entitled to spend a little

bit of cash for some tools to make the project easier. Not to mention

the fact that ANY excuse to buy power tools is a GOOD one. I bought

a 10" bandsaw and a 4 1/2" grinder.

Step 3

Using the bandsaw and the pine layup, I trimmed both rings into

the proper round shapes. Then I made a jig using a 12" lazy

susan and some plywood, fastened the layup to the lazy susan, placed

the whole thing on the bandsaw table and trimmed the edges from

the pine. Note that each ring was made using this same technique.

Step 4

Next, I made a template with the correct curve for the upper ring

from some masonite. With the trimmed pine still mounted to the lazy

susan, I began shaping the ring. This was a very noisy process.

I used a 36 grit pad and was able to shape the upper ring in about

4 hours.

Step

5

Some of the shaping was done while spinning the ring, but I'd say

that the majority was done just working a section at a time, checking

the shape with the template and moving on.

Step 6

When the rings were complete I marked the opening In the upper ring

and cut out the interior and the opening for the neons.

Step 7

The rings were spaced using some pine spacers which were glued and

screwed to the rings.

Step 8

Now apply the skin to the outside of the rings in order to form

the body. I chose a 1/8" Lauan Door skin material (also available

at Depot) and discovered some interesting things. First, the door

skin is actually just a very thin plywood. It's very inexpensive

but it's not without certain problems. First of all it bends better

in one direction than the other. Secondly when you cut a piece using

a jigsaw, it tears the heck out of one side. My advice to you is

to experiment with it a little bit and don't get too discouraged.

I got it to work and you can too.

Step

9

You can't simply cut rectangular pieces and expect them to fit around

the rings. I found it necessary to cut each piece with a slight

arc. When these were cut, I attached them using glue and nails.

Note also that I had to cut a 1/8 " recess into the bottom

of each ring so that the skin would fit flush with the edge of the

rings (refer to the illustration). I used a router, mounted into

a router table to do this.

Step 10

When the skin was on, I marked the arm sockets and cut them out

using the jig saw.

Step 11

The opening in the rear of the arm socket was made using some 3/8"

scrap plywood.

Step 12

The skin in the arm sockets was made from some very thin plywood

(1/32") which I purchased at a local hobby shop that specializes

in model aircraft. To cut the proper shapes, I used some manilla

folders to make templates. I transfered the shapes to the plywood,

cut the pieces and then using some thick cyanoacrylate glue, I glued

them into place. When they were in, I reinforced the installation

using some epoxy.

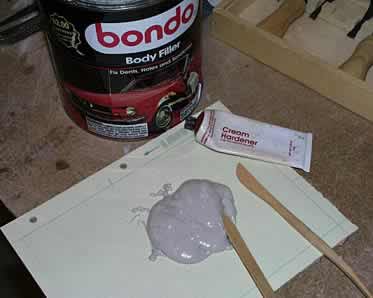

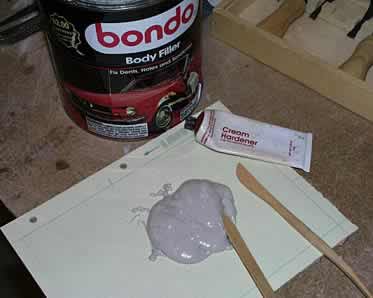

The

torso looks like a torso but I noticed that the skin pulled in slightly

towards the inner vertical braces. I used Auto body filler (Bondo)

to fill the imperfections.

Step 13

The trim was made using Bondo too. I initially tried using balsa

wood (refer to the photo in step 12), but that proved to be too

difficult since the trim has to attach to some very curved surfaces.

I also tried using foam tape, but it proved to be too soft and nothing

I tried to stiffen it up seemed to work. The Foam tape did prove

to be the best method for creating little mini forms for creating

the trim.

You

may have noticed that the opening for the neons looked a little

bit too wide at the top (refer to previous photos of un-primered

torso). When reviewing the drawings I noticed that I had made an

error on a dimension. I fixed the drawing and then, using Bondo,

I fixed my torso. This photo shows the corrected position.

Also

note that the opening is still NOT correct in these photos. The

corrected opening can be seen on the next page. At the time (Summer

98') I hadn't made the tracing of the "real"torso opening.

The

Bondo Trim Technique

The process of building the trim pieces is the same throughout the

torso. I took a few shots of the trim around the arm socket.

Using the foam tape, build a channel of appropriate size.

Mix a small quantity of Bondo

Fill the channel

Remove the foam

Cut off the excess

Do it again, until the finished product looks like this!

Step

14

Well there it is.

It's not perfect, but the flaws aren't too obvious. My original

intent was to make a fiberglass copy of this, but since I have absolutely

no intention of going into the torso building business, I decided

to abandon that idea.

|

Homemade

Torso #1

Homemade

Torso #1