Claw

Mold Making Claw

Mold Making

By

Scott Sanderson

Preface:

This page details the process of making molds to cast resin claws.

So many times when making a new part you are rushed and do not find

the time to document the process and take pictures, but this time

I made a conscious effort to document entire moldmaking the process.

I hope this gives a little insight on how much work and time it

takes to create a simple mold.

Day

1: First step is to create a highly detailed and refined master.

A little bondo, and some sanding and the claws were ready to go!

Time: 4 hours

Day

2: Mold making process is started by mounting the master on

a sheet of plexiglass so that it can be divided in half using molders

clay to form the first half of the mold. Special consideration must

be given to where the mold part line will be and also where the

mold will be poured from (in this case the very end of the claw).

Time: 3 hours

After the claw has been fully sectioned off the area where the clay

meets the master must be cleaned to create a sharp edge free of

debris and all clay residue must be removed form the master. Sides

must be added to the mold box define the width and thickness of

the mold. All gaps must be filled in to prevent silicon from leaking

out of the mold.

Once the mold box is finished its time to add dimples to the mating

surface so that the mold registers correctly.

Completed mold box.

An impression coat of silicon is brushed onto the master. This eliminates

bubbles and ensures full silicon coverage without voids or air bubbles.

The mold box is filled up the rest of the way with silicon. Notice

because of the angled tip on the claw this process will require

2 pourings. The silicon is allowed to cure overnight.

Day 3: The moldbox is tilted at an angle and the remaining portion

of the mold is filled with silicon and allowed to cure overnight.

Time: 15 minutes

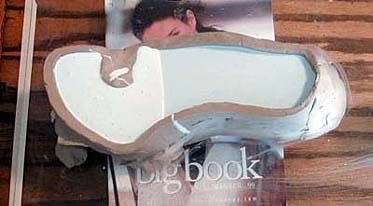

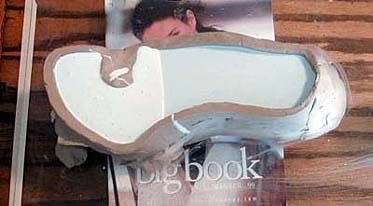

Day 4: After the silicon has cured the clay moldbox is carefully

removed. It is very important to remove all the clay, but critical

that the silicon is not peeled away from the master. If the seal

between the master and mold is broken it will allow silicon from

the second pouring to seep between the mold and master. Once all

the clay is removed the mold and master is cleaned with a brush

and water to remove any clay residue. Time: 2.5 hours

The mold is then remounted to the plexiglass and a new moldbox is

created from clay to form the second half of the mold.

Once the moldbox is completed for the second half, mold release

must be brushed onto the silicone to prevent the second half from

bonding to the first half. Mold release is only applied to the silicon

surfaces and not the master.

Once again the mold box is filled with silicon. Because of the anlge

on the claw, this side will also require two pourings. Note: It

is possible to do the mold in one pouring, but this will unnecessarily

add to the thickness of the mold and increase the cost of the mold

(silicon costs about $115 a gallon!). The mold is allowed to cure

overnight.

Day 5: Once the silicon has cured clay barriers are added to

create a smaller moldbox on top of the first pouring to cover the

remaining portion of the claw. This is allowed to cure overnight.

Time: 20 minutes

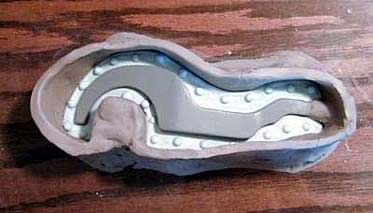

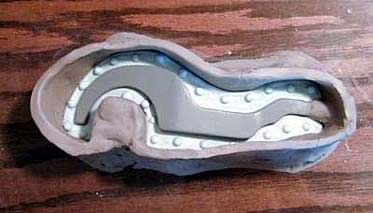

Day 6: After the silicon has cured the claw is removed and the

mold halves are separated from the each other and the master. The

halves are then cleaned to remove any remaining clay residue. The

first mold is completed and will sit for a few days to fully cure.

Time: 30 minutes

Day 6-7-8-9: Repeat steps from Day 2 through Day 6 to make the

mold for the second claw half. Note: the second claw mold could

be start in parallel with the first, however because of the time

required and amount of clay needed it was not practical. Time:

6 hours, 35 minutes

Day 9+: Now its finally time to make the first set of claws

and remove the flashing from the mold part line. Completed set of

resin claws pictured below. Note: without careful planning and execution

you can waste 9 days, a gallon of silicon, and still not have useable

molds! Time 1.5 hours

Total

hours to make the molds: 17 hours, 10 minutes.

Material cost: $115 (one gallon of silicon), plus clay, clay tools,

etc.

|

Claw

Mold Making

Claw

Mold Making